Services

Industries Served

We support industries with extreme operational conditions—shock loads, high temperatures, continuous duty cycles and contamination exposure:

Petrochemical & Refinery Plants

Bearings play a critical role in petrochemical and refinery plants, where continuous operation and extreme conditions are the norm. Our bearing solutions are designed to withstand high temperatures, heavy loads, chemical exposure, and constant vibration. They support essential equipment such as pumps, compressors, turbines, and rotating systems, ensuring stable performance and reduced downtime. Reliability and long service life are key factors in maintaining safe and efficient refinery operations.

Cement Plants & Crushers

In cement plants and crushing systems, bearings are exposed to extreme loads, dust, vibration, and continuous operation. Our bearing solutions are engineered to perform reliably in harsh environments, supporting crushers, mills, conveyors, and heavy rotating equipment. Designed for high load capacity and durability, they help reduce maintenance intervals and unplanned downtime. Consistent performance in demanding conditions is essential for efficient cement production.

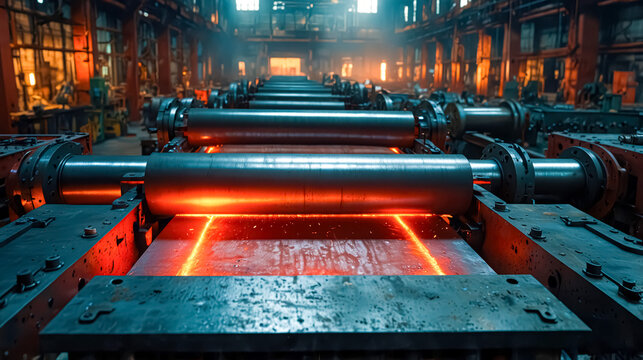

Paper, Textile & Wood Processing

Bearings used in paper, textile, and wood processing industries must operate with high precision under continuous loads and varying speeds. Our bearing solutions are designed to support rollers, shafts, and high-speed machinery while maintaining smooth operation and dimensional stability. They help reduce friction, minimize vibration, and ensure consistent production quality. Reliable performance is essential for maintaining efficiency and reducing downtime in these continuous-process industries.

Gearbox, Turbine & Heavy Machinery Manufacturers

Bearings are critical components in gearboxes, turbines, and heavy machinery, where precision, load capacity, and reliability directly affect system performance. Our bearing solutions are engineered to handle high torque, continuous rotation, and demanding operating conditions. They support stable power transmission, reduce mechanical stress, and extend equipment service life. Consistent accuracy and durability are essential for manufacturers operating in high-performance industrial environments.

GT, ST & CCPP Power Plants

In gas turbines (GT), steam turbines (ST), and combined cycle power plants (CCPP), bearings are essential for stable and efficient power generation. Our bearing solutions are designed to operate under high temperatures, high rotational speeds, and continuous load conditions. They support critical components such as turbines, generators, and auxiliary systems, helping to minimize vibration and ensure long-term operational reliability. Consistent performance is vital for maintaining efficiency and uninterrupted power output.

GT, ST & CCPP Power Plants

In gas turbine (GT), steam turbine (ST), and combined cycle power plants (CCPP), bearings play a vital role in ensuring stable and efficient power generation. Our bearing solutions are engineered to perform under high rotational speeds, elevated temperatures, and continuous operating loads. They support critical rotating equipment such as turbines, generators, and auxiliary systems, helping to reduce vibration and maintain operational stability. Reliable bearing performance is essential for efficiency, safety, and long-term plant operation.

Mining & Bulk Material Handling

In mining and bulk material handling operations, bearings are exposed to extreme loads, heavy shock, dust, and continuous operation. Our bearing solutions are designed to perform reliably in harsh environments, supporting crushers, conveyors, screens, and heavy rotating equipment. Built for high load capacity and durability, they help reduce maintenance requirements and unplanned downtime. Consistent performance is essential for safe, efficient, and continuous material handling operations.

Engineering & Technical Capabilities

Our engineering support provides a detailed analysis of bearing performance parameters and installation conditions. We assist with:

* Calculation of dynamic and static load ratings

* L10/L50 bearing life estimation

* Clearance class evaluation (C2, CN, C3, C4, C5)

* Cage type analysis (steel, brass, polyamide, reinforced polymer)

* Limiting and reference speed calculation

* Friction, heat generation and lubrication modelling

* Misalignment tolerance and shaft deflection review

* Failure mode interpretation based on ISO 15243

* Selection for shock load, vibration, high temperature and contamination conditions

We also offer cross-engineering for:

* Obsolete bearings

* Non-standard sizes

* Replacements for OEM-only parts

* Optimization of bearing types for improved MTBF (Mean Time Between Failures)

Quality Standards & Compliance

All supplied bearings comply with:

ISO 492 – ISO 199 – ISO 15243 – ISO 281

SKF Internal Quality & Traceability Procedures

Heat Treatment Certification (where available)

Upon request, we provide:

* Dimensional inspection reports

* Radial runout and roundness testing

* Vibration spectrum & noise testing

* NDT tests (MT/PT)

* Clearance measurement reports

* Seal and packaging audits

Inspection, TPI and Documentation

We provide full inspection and verification services, including:

* Pre-Shipment Inspection (PSI)

* Warehouse sampling inspection

* Vendor site audit

* Third-party inspection (TÜV, SGS, Bureau Veritas)

* Factory Acceptance Test (FAT)

Each shipment includes:

* Certificate of Origin (EU)

* Declaration of Conformity

* Packing List with serial numbers

* Technical documentation & traceability reports

Export, Packaging & Logistics

* EU-standard export packing (anti-humidity, anti-corrosion, VCI)

* Palletized shipments with packing optimization

* Full traceability labeling (batch, serial, heat code)

* Multi-country consolidation (Sweden + Germany + Italy in one shipment)

* International delivery: EXW – FCA – FOB – CIF – DAP